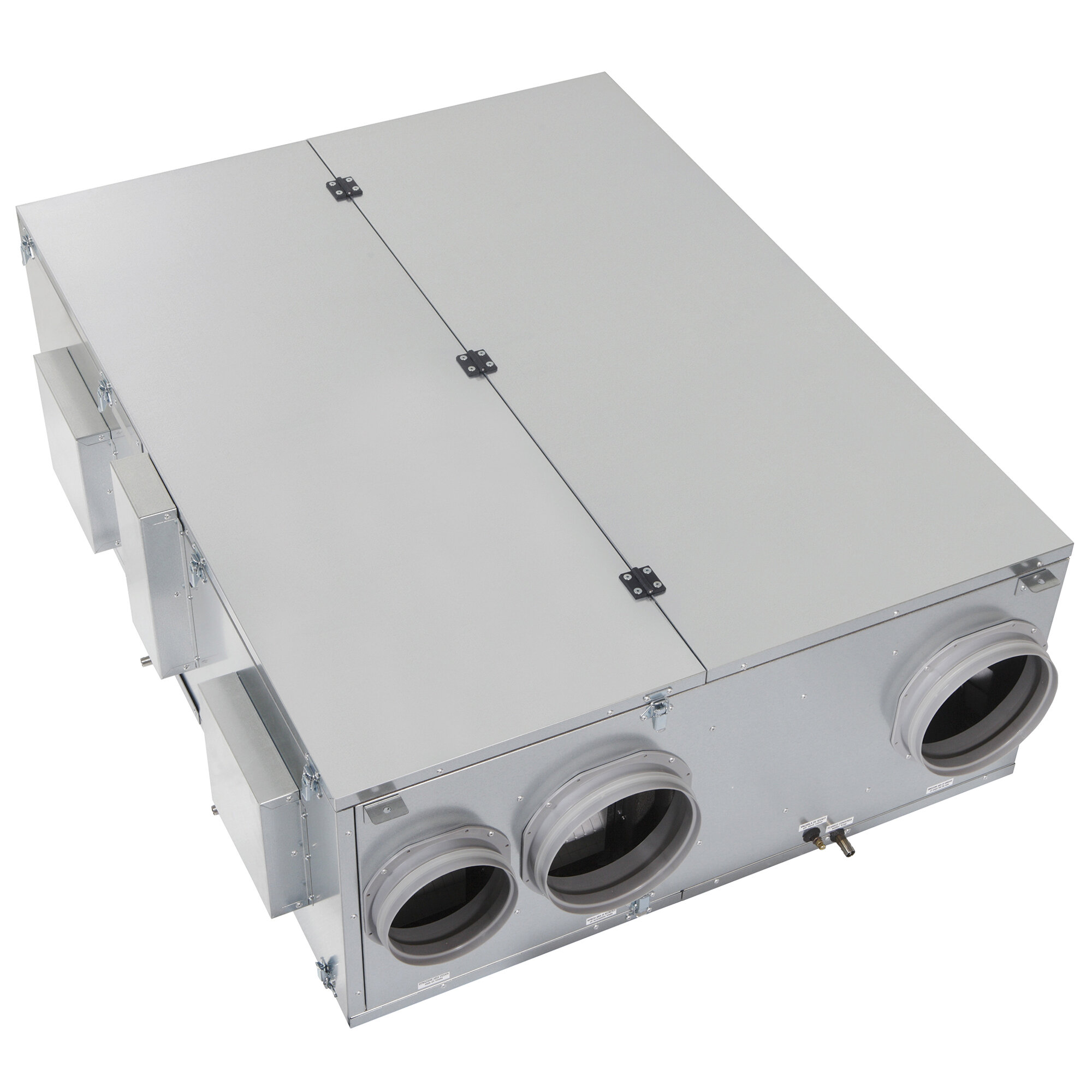

Recupera DRY-500, controlled mechanical ventilation unit with dehumidification

Recupera Dry-500 is an integrated Controlled Mechanical Ventilation (CMV) solution with dehumidification and air treatment for rooms in the home. By combining it with a radiant system and single air distribution system, the air can be treated throughout the different seasons, thus satisfying a complete range of comfort needs.

With Recupera Dry-500, the following air treatments are possible.

In Summer:

- air renewal with heat recovery (neutral air mode);

- dehumidification (neutral air mode);

- air renewal with heat recovery, with dehumidification and eventually cooling;

- air renewal without heat recovery (free cooling, bypass of recuperator).

In Winter:

- air renewal with heat recovery (neutral air mode);

- air heating;

- air renewal with heat recovery, with integration in heating;

- air renewal without heat recovery (free cooling, bypass of recuperator).

The air flow rates of Recupera Dry-500 can be set from the control panel; the electric fan speed is automatically adjusted to ensure the pre-set air flow rate in the distribution ducts and avoid any pressure drops.

The air introduced in the room can be composed of two air flows: the renewed flow with heat recovery, and the recirculated air flow.

The heating/cooling/dehumidification treatments always provide for a recirculated ambient air flow.

The renewed and recirculated flows can be combined or otherwise, depending on the flow rates and type of treatment to be carried out.

The machine is made of a galvanised sheet metal structure with special thermal and acoustic insulation, which contains: a direct expansion cooling circuit to dehumidify the air, a supplementary finned exchanger to be connected to the heating system for summer/winter integration, a high-efficiency air/air heat recuperator, motorised dampers to regulate the respective air flow rates, inspectionable G4 filters positioned in the respective unit air inlet ducts, two “brushless” variable-flow electric fans, one condensate drain pan, an electrical cabinet and remote control panel to be installed on a guide in a wall-mounted electrical cabinet.

The machine is equipped with a remote control panel to be mounted on a DIN rail in a wall-mounted electrical cabinet. The control panel is equipped with no. 3 terminal blocks for connection of:

- the Recupera Dry-500 electronic PCB;

- the digital inputs for the various functions to be activated;

- the two digital outputs with relay allowing activation of a circulating pump/zone valve/heat source/temperature controller and alarm in case of malfunction.

Functions that can be activated via the digital inputs:

- current season (as an alternative to the keypad command);

- renewal;

- dehumidification;

- heating/cooling;

- free cooling;

- reduction of air flow rates.

Settings available from keypad:

- activation of functions (as an alternative to digital consents);

- current time;

- current season (as an alternative to digital consent);

- supply and renewal air flow rates;

- neutral and integration supply temperature for each season;

- automatic renewal time slots (maximum 4);

- air flow rate reduction time slots (maximum 4).

It is also possible to read the values of the temperature sensors used by the machine, particularly useful during commissioning or operational testing.

Technical data

With Recupera Dry-500, the following air treatments are possible.

In Summer:

- air renewal with heat recovery (neutral air mode);

- dehumidification (neutral air mode);

- air renewal with heat recovery, with dehumidification and eventually cooling;

- air renewal without heat recovery (free cooling, bypass of recuperator).

In Winter:

- air renewal with heat recovery (neutral air mode);

- air heating;

- air renewal with heat recovery, with integration in heating;

- air renewal without heat recovery (free cooling, bypass of recuperator).

The air flow rates of Recupera Dry-500 can be set from the control panel; the electric fan speed is automatically adjusted to ensure the pre-set air flow rate in the distribution ducts and avoid any pressure drops.

The air introduced in the room can be composed of two air flows: the renewed flow with heat recovery, and the recirculated air flow.

The heating/cooling/dehumidification treatments always provide for a recirculated ambient air flow.

The renewed and recirculated flows can be combined or otherwise, depending on the flow rates and type of treatment to be carried out.

The machine is made of a galvanised sheet metal structure with special thermal and acoustic insulation, which contains: a direct expansion cooling circuit to dehumidify the air, a supplementary finned exchanger to be connected to the heating system for summer/winter integration, a high-efficiency air/air heat recuperator, motorised dampers to regulate the respective air flow rates, inspectionable G4 filters positioned in the respective unit air inlet ducts, two “brushless” variable-flow electric fans, one condensate drain pan, an electrical cabinet and remote control panel to be installed on a guide in a wall-mounted electrical cabinet.

The machine is equipped with a remote control panel to be mounted on a DIN rail in a wall-mounted electrical cabinet. The control panel is equipped with no. 3 terminal blocks for connection of:

- the Recupera Dry-500 electronic PCB;

- the digital inputs for the various functions to be activated;

- the two digital outputs with relay allowing activation of a circulating pump/zone valve/heat source/temperature controller and alarm in case of malfunction.

Functions that can be activated via the digital inputs:

- current season (as an alternative to the keypad command);

- renewal;

- dehumidification;

- heating/cooling;

- free cooling;

- reduction of air flow rates.

Settings available from keypad:

- activation of functions (as an alternative to digital consents);

- current time;

- current season (as an alternative to digital consent);

- supply and renewal air flow rates;

- neutral and integration supply temperature for each season;

- automatic renewal time slots (maximum 4);

- air flow rate reduction time slots (maximum 4).

It is also possible to read the values of the temperature sensors used by the machine, particularly useful during commissioning or operational testing.

Technical data

- Power supply: 230 Vac/1ph/50 Hz

- Maximum power consumption: 1080 W

- Maximum absorbed current: 5.4 A

- Refrigerant R410A (GWP = 2088)

- Inlet water temperature: 12 ÷ 18 ° C

- Maximum air flow that can be set: 500 m3/h

- Static pressure useful at maximum flow rate: 180 Pa

Renewal only operation:

- Air flow: 160 ÷ 300 m3/h

- Total absorbed power: 60 ÷ 140 W

- Thermal efficiency of the heat recovery unit in winter operation with internal air at 20 °C and R.H. 50%, and external air at -5 °C and R.H. 80%: 91.7% at minimum flow rate, 87.5% at maximum flow rate.

- Thermal efficiency of the heat recovery unit in summer operation with internal air at 26 °C and R.H. 65%, and external air at 35 °C and R.H. 50%: 86.7% at minimum flow rate, 80.4% at maximum flow rate.

Operation in renewal + recirculation (with dehumification):

- Nominal air flow (renewal + recirculation): 500 (210 + 290) m3/h

- Total nominal water flow (pre-cooling coil + condenser): 500 l/h

- Total nominal water pressure drop (pre-cooling coil + condenser): 11 kPa

- Total cooling capacity (from renewal + recirculation with dehumidification) (*): 4206 (826 + 3380) W

- Sensible cooling capacity (from renewal + recirculation with dehumidification) (*): 2094 (116 + 1978) W

(*) Internal ambient air intake: 26 °C; 65% RH; External ambient air intake 35 °C; 50% RH; Inlet water temperature 15 °C.

| Model | Max air flow rate [m³/h] | Q.ty per pack. | Code | |

|---|---|---|---|---|

Model DRY-500 | Max air flow rate [m³/h] 500 | Q.ty per pack. 1 pcs | Code 07300822 |