Topway: Heating Manifolds

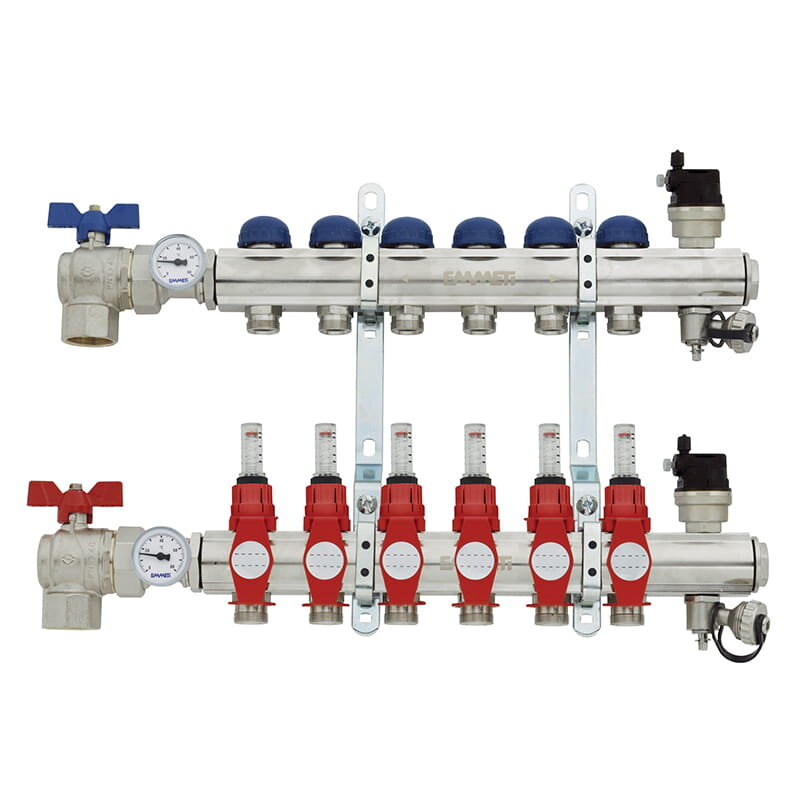

Topway manifolds can be employed in various system configurations, whether placed alone or in conjunction with a UFH mixing unit.

By installing electrothermic actuators coupled to a thermostat, it is possible to manage the temperature of each room using this type of heating manifold.

The thermostat may set the dispersed energy amount by controlling the water flow in each loop. The flow meters included in the manifold may also be used to alter the water flow setting in each loop.

During the manufacturing process, all Topway heating manifolds are thoroughly tested.

Why is it usual to install a flow balancing valve before the manifold?

In heating systems, the balancing valve is installed to allow the correct water flow setting, which means a proper distribution of the heat in the heated areas.

Setting the balancing valve correctly during the system's startup is important.

Is it possible to install any electrothermic head on the valves of the heating manifold?

No, on the market, it is possible to find electrothermic heads with different threads, which allow the connection to the heating manifold.

So, we recommend installing just Emmeti electrothermic heads on Emmeti manifolds.

What is the function of the differential by-pass?

A differential by-pass also called an overpressure valve, is a valve that guarantees the chosen pressure difference between the two points of the system where it is installed. It is normally possible to set the pressure difference between 0.1 and 0.5 bar.

How can I read the flow meter of a Topway heating manifold?

The scale of the flow meters installed on heating manifolds is in liters/minute. The correct setting depends on the calculation of the designer, which is normally between 1,5 and 2 lt/min for standard residential applications.

What does “Electrothermic head normally closed” mean?

A normally closed electrothermic head (NC) is designed to keep the water flow stopped if not connected. If the electrothermic head is equipped with a micro-end switch, the end switch is opened when the electrothermic head is closed, and it is closed when the electrothermic head is open.

Are the Topway heating manifolds supplied with loops opened or closed?

The flow bar of the heating manifold is supplied with the flow meters or with the lockshields, which are in a partially open position when supplied. The return bar of the heating manifold is supplied with the valves, which are closed during the production process.

Which is the maximum number of loops that can be connected to one circulator?

In a residential underfloor heating or cooling system, the length of the loops is variable, as is the distance between the manifold and the circulator.

So, the number of loops connectable to a circulator depends on the circulator's characteristics, the distance between the heating manifold and the circulator, and the number of loops.

What is the electronic wiring centre for electrothermic heads designed for?

The wiring centre is designed to simplify the connection between thermostats and actuators during the installation process. This way, it will be almost impossible to make mistakes during the installation, and the contact between electrical parts and water will be impossible during the system's life. The wiring centre can be installed inside the metal boxes, together with the manifolds.

How are electrothermic heads supplied?

To allow the pressure test of the system, without connecting the electrothermic heads, they are supplied partially open with the microswitch closed.

The electrothermic actuator has to be connected, electrically opened, and closed by disconnecting it to make it work. So the electrothermic head has to make one cycle.

How can I install the built-in box for potable water manifolds correctly?

To install it correctly, it is important to use protection against the concrete, which should be placed where the valve handles will stay.

The procedure is explained by a video available on the Emmeti website.