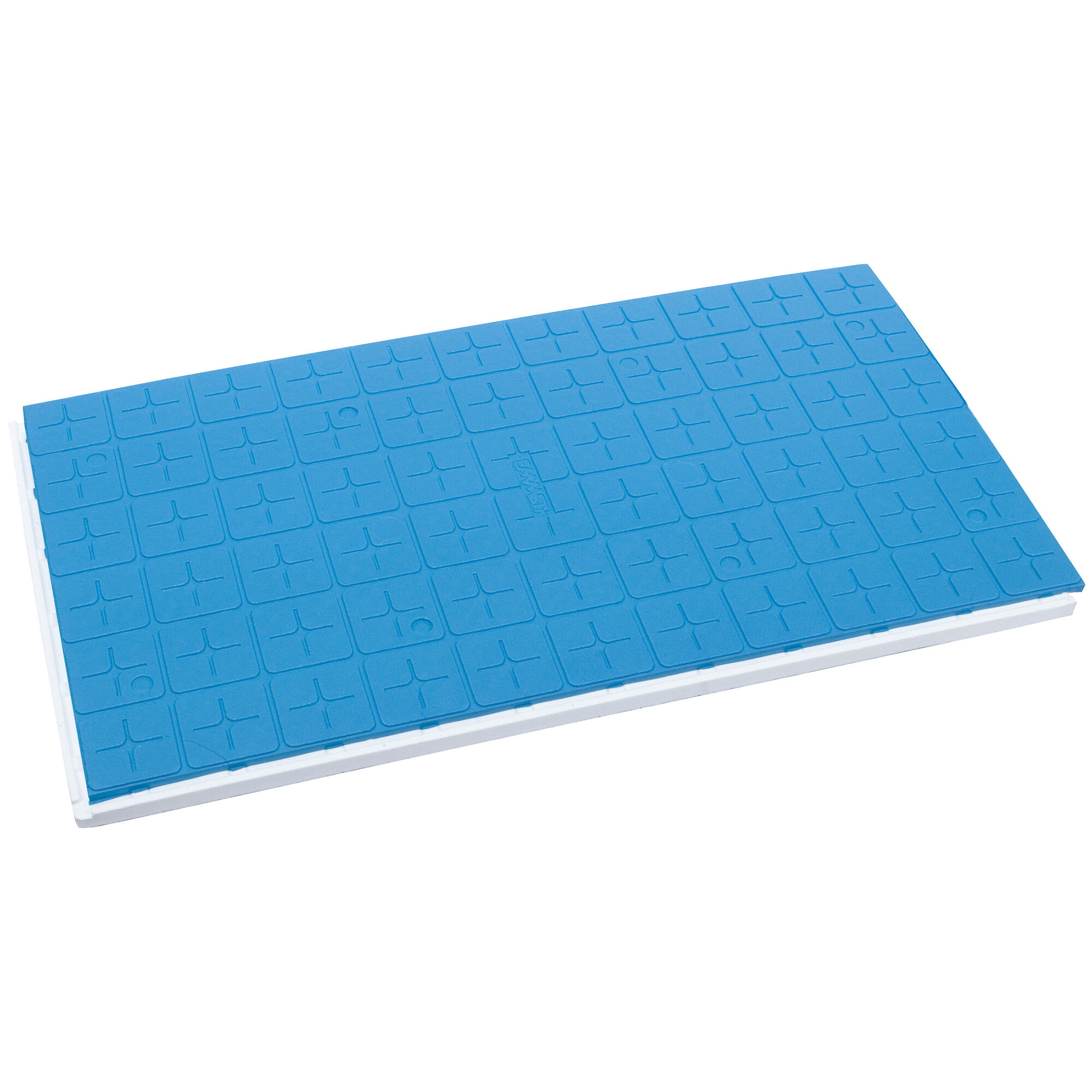

Plan Floor insulating panel

Plan Floor is the most efficient panel to develop the traditional underfloor heating system using clips.

This panel offers two advantages:

- the surface of the pipe is almost completely in contact with the screed

- pipe laying is not restricted, and serpentine layouts can be developed in irregular rooms

Insulating panels should have two basic requirements:

- thermal resistance

- compressive strength

The thermal resistance of Plan Floor panels is greater than the minimum value established by the standard EN 1264-4 (0.75 m²K/W, underfloor heating above a heated room).

In the years, expanded polystyrene has confirmed its suitability to be subjected to compressive loads for long periods without sagging.

Plan Floor simplifies the installation of the insulation and the piping thanks to the interlocking grooves and the guide cavities that allow to correctly install the pipes according to the distances of the design (5x5 cm mesh).

The film is heat bonded to the panel, which produces a homogeneous material, with excellent characteristics of:

- resistance to screed humidity

- resistance to impact and light foot traffic during installation

Plan Floor features male-female interlocking grooves that, combined with the characteristics of the surface film, make the insulating layer waterproof and make it unnecessary to cover the panels with polyethylene sheets.

The Plan Floor panel is used as an insulating and support layer for the piping in underfloor heating and cooling systems.

It is used as an insulating and support layer for the piping in underfloor heating and cooling systems. Its physical and mechanical characteristics make it suitable for use in any type of building, especially large or irregularly shaped rooms, where the pipes can be fixed with tacker clips, mesh type clips, and guide bars for pipes.

Plan Floor panels are produced in accordance with standard UNI EN 13163 (thermal insulation for buildings - factory made expanded polystyrene (EPS) products) and certified according to Regulation (EU) N. 305/2011.

This panel offers two advantages:

- the surface of the pipe is almost completely in contact with the screed

- pipe laying is not restricted, and serpentine layouts can be developed in irregular rooms

Insulating panels should have two basic requirements:

- thermal resistance

- compressive strength

The thermal resistance of Plan Floor panels is greater than the minimum value established by the standard EN 1264-4 (0.75 m²K/W, underfloor heating above a heated room).

In the years, expanded polystyrene has confirmed its suitability to be subjected to compressive loads for long periods without sagging.

Plan Floor simplifies the installation of the insulation and the piping thanks to the interlocking grooves and the guide cavities that allow to correctly install the pipes according to the distances of the design (5x5 cm mesh).

The film is heat bonded to the panel, which produces a homogeneous material, with excellent characteristics of:

- resistance to screed humidity

- resistance to impact and light foot traffic during installation

Plan Floor features male-female interlocking grooves that, combined with the characteristics of the surface film, make the insulating layer waterproof and make it unnecessary to cover the panels with polyethylene sheets.

The Plan Floor panel is used as an insulating and support layer for the piping in underfloor heating and cooling systems.

It is used as an insulating and support layer for the piping in underfloor heating and cooling systems. Its physical and mechanical characteristics make it suitable for use in any type of building, especially large or irregularly shaped rooms, where the pipes can be fixed with tacker clips, mesh type clips, and guide bars for pipes.

Plan Floor panels are produced in accordance with standard UNI EN 13163 (thermal insulation for buildings - factory made expanded polystyrene (EPS) products) and certified according to Regulation (EU) N. 305/2011.

| Model | Insulation thickness [mm] | Thermal resistance [m²K/W] | Density [kg/m³] | m²/pack | Code |

|---|---|---|---|---|---|

Model 1100 x 600 x 30 / H30 | Insulation thickness [mm] 30 | Thermal resistance [m²K/W] 0,9 | Density [kg/m³] 30 | m²/pack 10,56 | Code 28130072 |